According to statistics of the Google Blogger, the blog has reached the milestone of 10'000 views Today.

The increasing number of visitors encourages me to continue writing about my views and opinions of Embedded stuff.

According to Blogger Stats, Top-5 origins of visitors in order of magnitude are: US, Finland, Poland, UK, and Germany. US and UK are as expected, as I'm trying to do my best in writing in English. Finland is the country of my origin. The company has R&D center in Poland also, which explains visitors from that country. In the list there is one country, Germany, which does not have any other excuse except they have found the blog interesting enough. Originally I expected some interest from Sweden as well, but that haven't happened yet.

There are many writings in the net stating Blogger Stats is not as accurate as Google Analytics. For example, bots may be counted as visitors. On the other hand, as dynamic views are not enabled at the moment, every visitor is counted as one, regardless how many blog writings are read within one visit. Thus the number of individual blog posting reads is perhaps 2-10 times higher.

Thank you for reading. Let's keep going on!

All aspects of Embedded Systems; technology news, hacking projects, popular electronics, industry trends, reviews, and forecasts, etc.

Wednesday, April 23, 2014

Monday, April 14, 2014

Wandboard and Sumo robots

The Wandboard is a low-cost Cortex-A9 board based on the Freescale i.MX6 family of SoCs.

More and more non-profit open platforms are popping up in the spirit of Raspberry Pi. Wandboard is one among them. The board was released already at the end of year 2012, but I first time familiarized myself with it at Embedded World in Nuremberg, at Freescale department. Also at Scandinavian Electronics Event in Stockholm, Freescale demonstrated Wandboard with Rightware Kanzi 3D graphics technology at their booth.

Wandboard is a Single Board Computer (SBC), which consists of two PCBs.

Isn't that contradictory? However, the solution is nice from embedded

systems development point of view. One can use the 2-board product as

the basis of development, and then just plug the CPU-module into the end

product once the custom motherboard is ready. Wandboard MCU modules are

sold separately in bunch of ten.

Even if Wandboard was new to me, it was already in use by our engineers. In our R&D center at Wroclaw, Poland, employees have organized a hobby robot competition with small autonomous Sumo-robots. Currently there are 5 teams with 3-5 members in each programming at their spare time.

The core organizers of the competition have developed a common electromechanical platform for all the teams, based on custom PCBs. For higher level control, each team has then chosen a CPU or MCU board of their own. For low level control, there is TMS320 DSP processor in the platform together with power source, H-bridge driver, sensors, etc.

One of the teams selected Wandboard Quad. They also tough out of the box, and put the robot frame upside down, to balance with two tires just like the Segway, with help of gyros and accelerometers. That's quite something!

The Wroclaw site is not only active internally, but they are participating academic and other external events, for example by sponsoring LabVIEW programming competition and the Sumo robot competition at local technical university. The HR lady organized a drawing competition for kids during the previous event. Now there are nice drawings all around walls of corridors, kitchens, and meeting rooms of the office.

More and more non-profit open platforms are popping up in the spirit of Raspberry Pi. Wandboard is one among them. The board was released already at the end of year 2012, but I first time familiarized myself with it at Embedded World in Nuremberg, at Freescale department. Also at Scandinavian Electronics Event in Stockholm, Freescale demonstrated Wandboard with Rightware Kanzi 3D graphics technology at their booth.

|

| Wandboard. Picture from Wandboard web site. |

Even if Wandboard was new to me, it was already in use by our engineers. In our R&D center at Wroclaw, Poland, employees have organized a hobby robot competition with small autonomous Sumo-robots. Currently there are 5 teams with 3-5 members in each programming at their spare time.

The core organizers of the competition have developed a common electromechanical platform for all the teams, based on custom PCBs. For higher level control, each team has then chosen a CPU or MCU board of their own. For low level control, there is TMS320 DSP processor in the platform together with power source, H-bridge driver, sensors, etc.

|

| Balancing Sumo robot with Wandboard. |

The Wroclaw site is not only active internally, but they are participating academic and other external events, for example by sponsoring LabVIEW programming competition and the Sumo robot competition at local technical university. The HR lady organized a drawing competition for kids during the previous event. Now there are nice drawings all around walls of corridors, kitchens, and meeting rooms of the office.

|

| Kids' robot drawings. |

Sunday, April 13, 2014

RaspberryPi for professional use

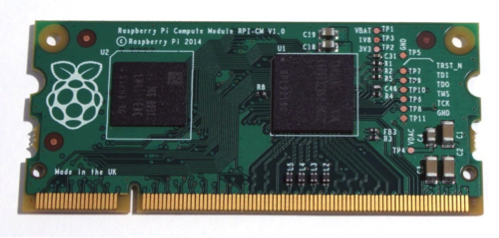

Raspberry foundation will release a new CPU-module with form-factor of SODIMM-memory.

Raspberry Pi has become extremely popular among hobbyists. The win of the concept is not because of it's technological marvel, but essentially because of the great ecosystem and support.

Raspberry Pi is known to be used as a basis of some commercial embedded solutions as well, even if RPi as such is not very suitable for the purpose: connectors are inconveniently located at all edges of the board, limited extension header, and lack of mechanical support. Compare for example to BeagleBone Black, which is much better suitable to be used as a part of other products.

A week ago, Raspberry foundation published their plans to release a new CPU-module within the summer. The module has form-factor of SODIMM memory module, perhaps the most popular format of CPU-modules at the day. The module has Flash-memory on board, thus separate SD-memory card is not necessary.

For sure, this new product is intended for professional use. Very few hobbyist has capability to design and manufacture motherboards of their own. Perhaps the community will help here and some application specific motherboards will be available in the future.

For professional purposes this module is good, as now it does make sense to have RPi in your design. Why RPi module instead of some other CPU module? First of all, RPi has the winning ecosystem, having software support that exceeds any commercial vendor. Secondly, RPi modules are expected to be rather inexpensive. Retail price is not published yet, but for sure it will be lower than the Raspberry SBC models available at the day.

For what RPi is then good for? The Broadcom BCM2835 SoC is actually a GPU with added general purpose CPU core (ARM9), thus it can do graphics decoding and 3D rendering efficiently by hardware. Broadcom recently released more specifications of the GPU side, thus more open drivers are expected soon. So as an answer, RPi module is suitable for any embedded products having local 2D/3D graphical display for HMI in use.

According to unverified sources, Broadcom is also planning to start selling the module, as in it's ripped-down format it only contains silicon IP of Broadcom's own. According to the same source, the current RaspberryPi does not use the SoC in most energy efficient way, and perhaps in this new product the power consumption will be lowered down to mobile phone level.

Availability via Broadcom is essential to have creditability of availability good enough for any commercial products with long life-cycles like in case of industrial and medical applications.

Raspberry Pi has become extremely popular among hobbyists. The win of the concept is not because of it's technological marvel, but essentially because of the great ecosystem and support.

Raspberry Pi is known to be used as a basis of some commercial embedded solutions as well, even if RPi as such is not very suitable for the purpose: connectors are inconveniently located at all edges of the board, limited extension header, and lack of mechanical support. Compare for example to BeagleBone Black, which is much better suitable to be used as a part of other products.

A week ago, Raspberry foundation published their plans to release a new CPU-module within the summer. The module has form-factor of SODIMM memory module, perhaps the most popular format of CPU-modules at the day. The module has Flash-memory on board, thus separate SD-memory card is not necessary.

|

| Picture of the RPi CPU-module from RaspberryPi web site. |

For professional purposes this module is good, as now it does make sense to have RPi in your design. Why RPi module instead of some other CPU module? First of all, RPi has the winning ecosystem, having software support that exceeds any commercial vendor. Secondly, RPi modules are expected to be rather inexpensive. Retail price is not published yet, but for sure it will be lower than the Raspberry SBC models available at the day.

For what RPi is then good for? The Broadcom BCM2835 SoC is actually a GPU with added general purpose CPU core (ARM9), thus it can do graphics decoding and 3D rendering efficiently by hardware. Broadcom recently released more specifications of the GPU side, thus more open drivers are expected soon. So as an answer, RPi module is suitable for any embedded products having local 2D/3D graphical display for HMI in use.

According to unverified sources, Broadcom is also planning to start selling the module, as in it's ripped-down format it only contains silicon IP of Broadcom's own. According to the same source, the current RaspberryPi does not use the SoC in most energy efficient way, and perhaps in this new product the power consumption will be lowered down to mobile phone level.

Availability via Broadcom is essential to have creditability of availability good enough for any commercial products with long life-cycles like in case of industrial and medical applications.

Thursday, April 10, 2014

Generic technology exhibitions loosing popularity

Scandinavian Electronics Event was organized in Stockholm Kista within this week.

In Sweden the same effect is clearly seen as in Germany, which I reported in my previous posting about Hannover messe.

Scandinavian Electronics Event is rather generic event in domain of electronics; there are PCBA manufacturing machine makers, EMS providers, component dealers, silicon technology providers, some software suppliers, and consulting houses in one place without clear focus. Other ends of the convention hall are like day and night.

My company attended S.E.E. as an exhibitor some years back, already at that time it was disappointment, with very little relevant contacts and low number of visitor. At that time there was merely 5000 visitors during the 3 day show. We decided not to go anymore.

According to published numbers of two first days, it looks like the total number of visitors will decrease down to 4000. That's definitely too little to justify a three-day event. I discussed with some exhibitors familiar to me, and they told it's not only disappoiment, but also a disaster to put so much effort for pretty much noting.

Meanwhile Scandinavian Electronics Event is struggling for it's existence, Embedded Conference Scandinavia reported 50% gain in number of visitors last time. ECS is smaller than SEE, but very well focused. Every visitor is potentially relevant contact. My company will attend ECS as an exhibitor this year, just like we have done for the previous 5 years. And once again I will prepare a presentation to be held there. ECS will be organized in the very same place at Kista mässan in November.

Why does it goes like that? Quite obviously at the Internet era, trade fairs and exhibitions are not needed to get information about new product releases and what's going on in general. Why are smaller tightly focused professional events gaining popularity then? It's not about new product information, but getting and maintaining professional contacts, socializing, "to see and to be seen among professionals of your kind", somehow comparable to academic conferences.

In Sweden the same effect is clearly seen as in Germany, which I reported in my previous posting about Hannover messe.

Scandinavian Electronics Event is rather generic event in domain of electronics; there are PCBA manufacturing machine makers, EMS providers, component dealers, silicon technology providers, some software suppliers, and consulting houses in one place without clear focus. Other ends of the convention hall are like day and night.

My company attended S.E.E. as an exhibitor some years back, already at that time it was disappointment, with very little relevant contacts and low number of visitor. At that time there was merely 5000 visitors during the 3 day show. We decided not to go anymore.

According to published numbers of two first days, it looks like the total number of visitors will decrease down to 4000. That's definitely too little to justify a three-day event. I discussed with some exhibitors familiar to me, and they told it's not only disappoiment, but also a disaster to put so much effort for pretty much noting.

Meanwhile Scandinavian Electronics Event is struggling for it's existence, Embedded Conference Scandinavia reported 50% gain in number of visitors last time. ECS is smaller than SEE, but very well focused. Every visitor is potentially relevant contact. My company will attend ECS as an exhibitor this year, just like we have done for the previous 5 years. And once again I will prepare a presentation to be held there. ECS will be organized in the very same place at Kista mässan in November.

Why does it goes like that? Quite obviously at the Internet era, trade fairs and exhibitions are not needed to get information about new product releases and what's going on in general. Why are smaller tightly focused professional events gaining popularity then? It's not about new product information, but getting and maintaining professional contacts, socializing, "to see and to be seen among professionals of your kind", somehow comparable to academic conferences.

Tuesday, April 8, 2014

Maschinenbau

Why does German industry so well at the moment?

German industry has long tradition of "Maschinenbau" (machine construction). Today, this is seen by the huge number of companies designing and constructing machinery of all kind.

Many of those Maschinenbau companies are focusing on certain very narrow and high-tech area, typically making machines which are used in making other machines. Meanwhile other industries moved manufacturing to Asia, Maschinenbau companies have pretty much kept production in their own hands locally.

Typically these products are expensive and manufactured in small volumes, thus the cost benefit of mass production in Asia is not achieved. More important is to have highly skilled workers in assembly, and have fast feedback cycle from production back to the design department.

At the Hannover messe, I spotted number of products designed by my company, as usually. Among those customer references, I have picked up here couple of good examples of the spirit of Maschinenbau.

Beamex provides world class field calibrators and communicators. Beamex is known for high-accuracy calibrators, and is the market leader on that specific sector. Not only sensors on field, but also the calibrator by itself needs to be calibrated every then and now. After-sales service is important part of the business. Needles to say that the company is doing very well and breaks it's own records year after year.

Epec design and manufacture control systems for vehicle environments, intended for companies how construct professional moving working machines like harvesters for example. Epec products are especially designed for hars environments, including vibration, moisture, and very wide temperature range. Epec is also doing very well, even if their business is more sensitive to the turbulence of global economy.

These two Finnish companies are good examples of why the German industry is doing so well. By focusing on very high tech domain and having production of their own, this kind of companies are not threatened by Asian competition, but instead they are exporting to China in fact.

German industry has long tradition of "Maschinenbau" (machine construction). Today, this is seen by the huge number of companies designing and constructing machinery of all kind.

Many of those Maschinenbau companies are focusing on certain very narrow and high-tech area, typically making machines which are used in making other machines. Meanwhile other industries moved manufacturing to Asia, Maschinenbau companies have pretty much kept production in their own hands locally.

Typically these products are expensive and manufactured in small volumes, thus the cost benefit of mass production in Asia is not achieved. More important is to have highly skilled workers in assembly, and have fast feedback cycle from production back to the design department.

At the Hannover messe, I spotted number of products designed by my company, as usually. Among those customer references, I have picked up here couple of good examples of the spirit of Maschinenbau.

|

| Beamex MC6 field calibrator. |

|

| Epec 6107 Display Unit with Cortex-A9 multi-core CPU. |

These two Finnish companies are good examples of why the German industry is doing so well. By focusing on very high tech domain and having production of their own, this kind of companies are not threatened by Asian competition, but instead they are exporting to China in fact.

Monday, April 7, 2014

Hannover messe

Once again, it's the time of the world biggest industrial fair in Hanover within this week.

Digital industry, Industrial internet, or Industry 4.0 as German goverment calls it, is one of the leading themes of the event. It's pretty much in line with Embedded World in Nuremberg having Internet of Things as the leading theme. It's all about smart and connected world.

As being in Germany, automotive industry has strong position, of course. Electric cars are especially in the center of interest. Germans are known for their interest towards sustainable economy, one can see windmill parks and solar cell plants all over the countryside.

Hannover fairground is the largest in the world. However, this year it look's like 30% of convention halls are unused, and the number of exhibitors has decreased from average 6500 to just over 5000. German industry and economy in general are doing well, that's not the reason for deduction.

All in all it looks like this kind of general trade fairs are loosing popularity, and giving space to smaller and more dedicated ones. For example Embedded World reported new record this year, having 15% gain in number of exhibitors and almost 20% gain in number of visitors.

Digital industry, Industrial internet, or Industry 4.0 as German goverment calls it, is one of the leading themes of the event. It's pretty much in line with Embedded World in Nuremberg having Internet of Things as the leading theme. It's all about smart and connected world.

As being in Germany, automotive industry has strong position, of course. Electric cars are especially in the center of interest. Germans are known for their interest towards sustainable economy, one can see windmill parks and solar cell plants all over the countryside.

|

| Electric and hybrid cars presented by Volkswagen. |

All in all it looks like this kind of general trade fairs are loosing popularity, and giving space to smaller and more dedicated ones. For example Embedded World reported new record this year, having 15% gain in number of exhibitors and almost 20% gain in number of visitors.

Wednesday, April 2, 2014

Simple HIL example

Hardware In the Loop (HIL) simulation, the way it is described in Wikipedia, is considered as an expensive and time consuming method only applied in development of most complex and safety critical applications, like in automotive or aviation domains. Equipment needed for testing an ECU is expensive for sure, but there is also possibility for more lightweight approach in case of more conventional embedded systems development.

Here is an example from my hobby project. Last Christmas I got my interest to model trains to rise again after 25 years, as told in earlier posting Fully automated model train control. As a part of that, I have implemented a RF control for locomotives with two-way communication, using 868 MHz radio.

|

| Model train, RaspberryPi with Sug-GHz RF dongle and train control unit (green antenna). |

|

| Block diagram of the locomotive control unit. |

|

| Functional principle of the odometer. |

|

| HIL setup with target hardware, NI myDAQ and ISP programming device. |

| ||||

| Software development environment. |

Now the questions is only how good the plant (physical process) simulation model is? In my case, I just had some delay in feedback from PWM to tachometer. That was good enough for the simple problem given. I didn't had to simulate all the physical phenomena like mass, inertia, friction, etc. The drawback is that testing in real physical environment can not be completely avoided.

What is the lesson here? Even smallest embedded projects can benefit from HIL simulation approach, even if no complete plant model exists. In the case of this example, I claim I got benefits in software development, even if I had to learn LabVIEW programming first. A developer already familiar with the given simulation tool can get benefits much faster.

Subscribe to:

Comments (Atom)